Digital tools for machine support and control

The Digital tools for decision support and machine control theme focuses on the development of high-level software layers for remote machine management at different spatial scales (plots, farms, long distances), integrating information gathering and multi-source data management (directly from the machine, or from complementary fixed or mobile sensor networks).

Existing equipment and infrastructure

Existing original and structuring means of investigation can be mobilized.

Within the platform

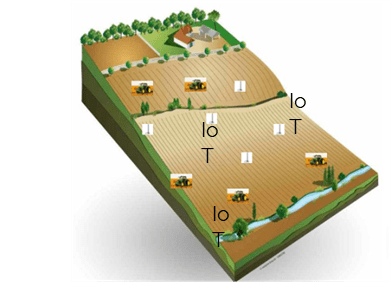

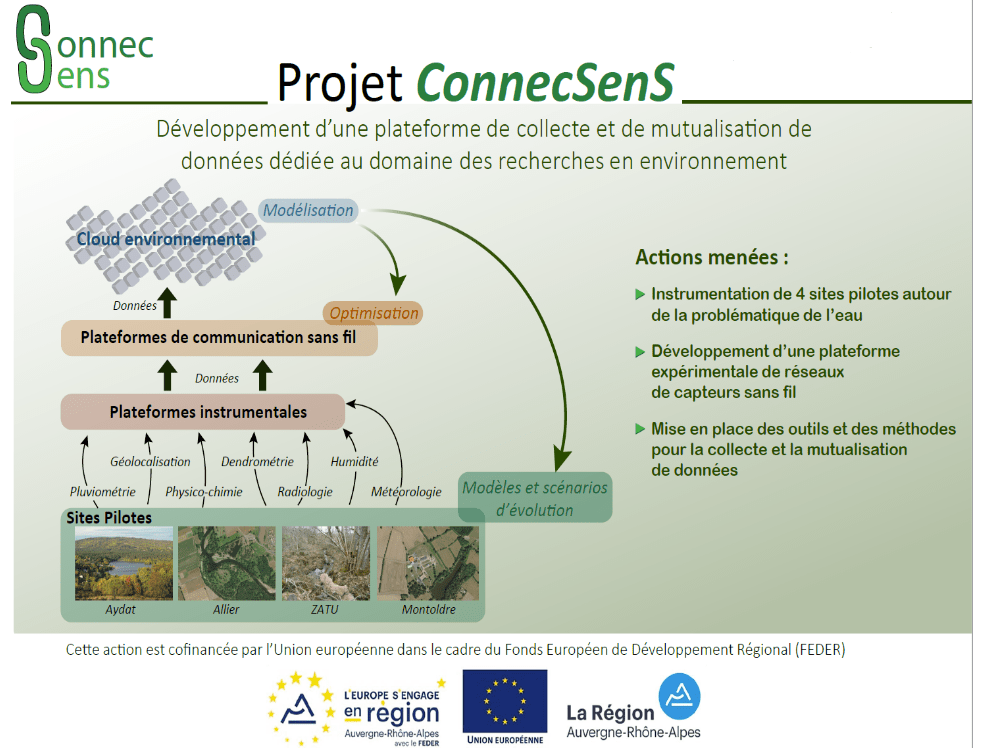

The AgroTechnoPôle draws on the resources already developed by its partners – for example, the work carried out by INRAE-TSCF (COPAIN team) on IoT technologies, sensor networks and information systems as part of the ConnecSens project and deployed at the Montoldre experimental site.

Illustration of the ConnecSenS project, installed at Montoldre, applied to the study of the hydric functioning of agrosystems.

The ConnecSenS project has demonstrated its ability to develop low-energy, communicating sensor networks for the environment and agriculture. Data management is carried out within flexible, scalable, real-time data warehouses.

New equipment and infrastructure

New structuring facilities and infrastructures

Section 3: Digital twins workshop

Digital environments, and in particular digital twins (see Figure XX ), are now indispensable tools for accelerating new technological and digital developments.

The AgroTechnoPôle platform has chosen to develop and offer these virtual tools as part of its RESEARCH / ENGINEERING / TESTING / TRAINING offer to interested external partners.

The Digital Twins workshop, initially designed for agricultural robotics, integrates various sub-assemblies. The first subset is used to describe and represent models of the robot itself (dimensional characteristics, transmission stages, steering actuators, etc.) with varying degrees of representativeness to be agreed. A second subset is dedicated to modeling the various sensors (proprioceptive or exteroceptive) used, including interaction models with the environment, as well as more or less advanced disturbance models. User-friendly interface tools enable scenarios to be set up to reproduce machine operating situations. This last sub-assembly includes a digital model of the robot’s environment, which in our case will correspond to and reproduce exactly the experimental site at the AgroTechnoPôle in Montoldre (03), with its plots of land, farm roads, new outdoor infrastructures currently under construction, and existing and new buildings.

Digital modeling of the experimental site at the AgroTechnoPôle platform in Montoldre (03)

The strength of AgrotechnoPôle’s offer will lie in the layout and faithful juxtaposition of this 3D digital model with the actual physical environment of the entire Montoldre experimental site. So, once the results have been validated in the virtual world, the partner will have exactly the same environment in which to develop his solution. Interactions between the virtual and real worlds will of course also be possible as part of HIL (Hardware In the Loop) approaches.

Developments in this digital twins workshop, which has now been defined and will shortly enter its realization phase with the involvement of specialized players in the field, will constitute a powerful virtual tool for the realization of :

- the design of new agricultural robot architectures and assessments of their dynamic behavior even before the first physical prototype has been produced, providing significant advantages in terms of time and cost savings

- performance qualification in terms of mobility, motorization, energy, safety functions, etc., of agricultural robots and vehicles prior to full-scale physical testing campaigns.

- development and evaluation of high-level supervisory tasks (cooperation of homogeneous and heterogeneous robots, communication links, etc.) or any other characterizations concerning the development of AI-based modules, deep learning facilitation, database creation, preventive maintenance, training, etc.

The Digital Twins workshop in an operating mode will guarantee the industrial partner full confidentiality in the conduct of developments and exploitation of results.

Transcription of the behavior of a mobile machine in a situation close to existing buildings on the Montoldre experimental site.